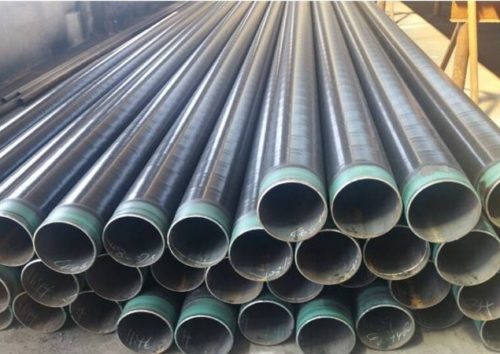

Pipline Coating Service

Pipeline anticorrosion

From the earliest coating types of petroleum asphalt and coal tar to the diverse coating types such as FBE, 2FBE, 2LPE, 3LPE, 3LPP, inner coating, foam-jacket composite insulation and so on, IMMI can now take on anticorrosion and insulation projects of various structures.

Thermal shrinkage products for pipeline anticorrosion

Thermal shrinkage products for pipeline anticorrosion are specially designed for steel transmission pipes and are mainly applied in anticorrosion of welded junctions, joints, flanges and also entire steel pipes as well as steel bends. The products are suitable for double-layer polyethylene anticorrosion, three-layer polyethylene anticorrosion, three-layer polypropylene anticorrosion, FBE and 2FBE anticorrosion, as well as anticorrosion of epoxy asphalt and coal tar for welded junctions and bending areas.

Concrete weight coating for marine pipelines

We own an operation line of concrete weight coating and can take up all kinds of pre-processing of concrete weight layer for marine pipelines.

Anticorrosion for metal structure products

We have sets of equipment of rust removal and coating for metal structure products, and can take up anticorrosion and insulation projects of metal gas tank and other metal structure products.

Bend anticorrosion

From the successful development of mechanized anticorrosion operating line suitable for bends of different diameters to practical production, quite a number of operation have been conducted, including FBE and cold tape coating, DUO-FBE coating, liquid epoxy coating and inner coating, etc.

Negative pole protection

In addition to coating anticorrosion,we also can apply electrochemical anticorrosion to protect clients’ equipment, and is capable of design, construction and test of negative pole protection in a comprehensive way.

Sideline business

Production of anticorrosion equipment

We have the ability to design and produce all kinds of anticorrosion equipment. The multi-function external anticorrosion operating line and inner coating operating line for pipelines, both of which are designed by the company itself, have stood the test of large projects both at home and abroad and gained common appreciation from clients.

Technical consultation on anticorrosion projects

Thanks to the talent reserves, we are capable of technical consultation on metal pipeline and metal structure anticorrosion for domestic and overseas clients. According to the consultation results, clients can evaluate the anticorrosion structure design and construction quality of the project in progress and then decide the maintenance and renewal scheme for pipes already in use.

Supply of pipelines and bends

We have established close cooperative relationship with several manufacturers of steel pipe and bend all over the country, and therefore can provide one-stop service, considering the need of different clients. It supplies seamless steel pipes, spiral-welded steel pipes, high frequency resistance welding steel pipes, double-face submerged arc straight welding steel pipes and stewed bends in different diameters.